Multi-Objective & Multi-Constrained Parametric Optimization Algorithm

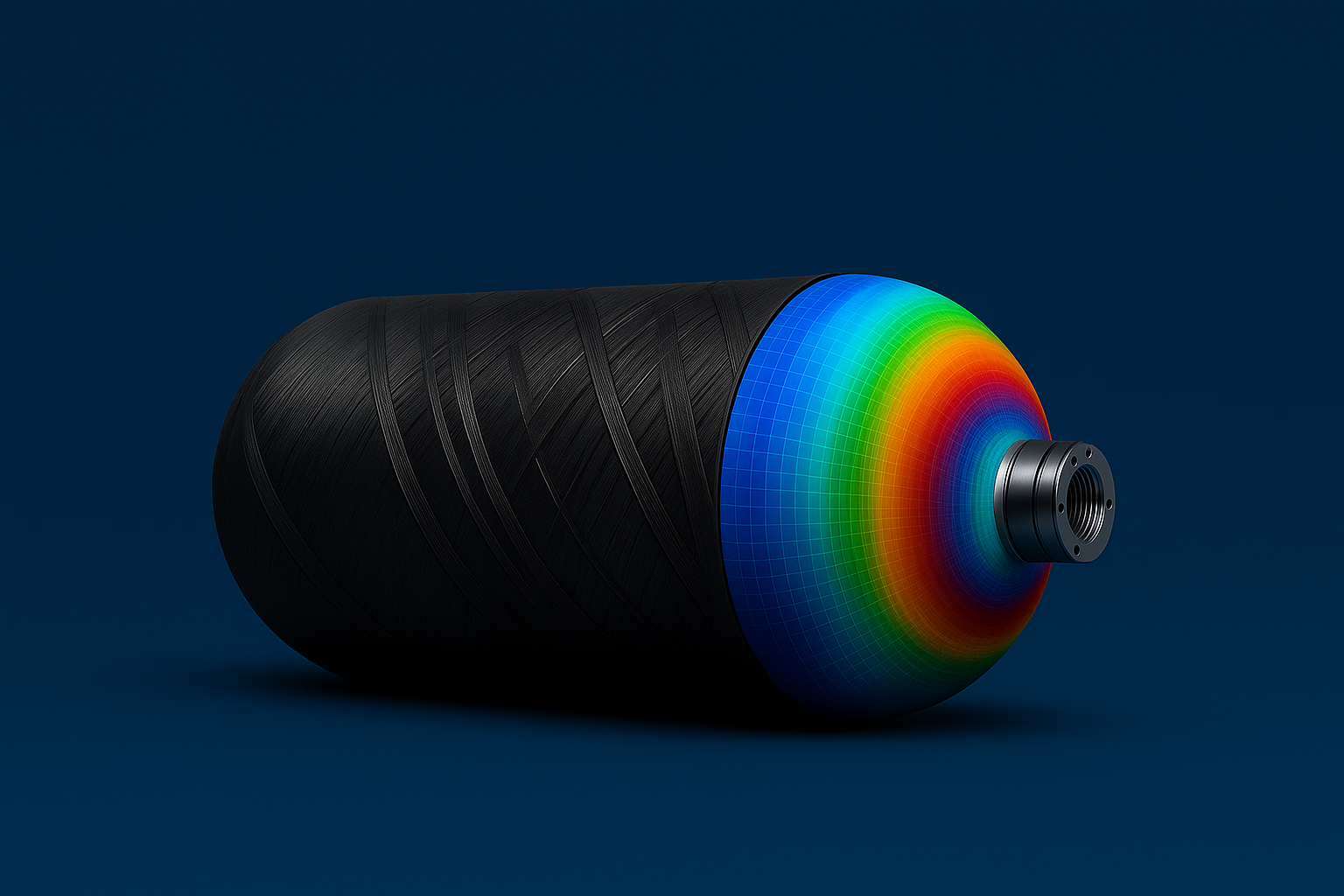

Our advanced design optimization algorithm enables the development of robust and lightweight COPVs (Composite Overwrapped Pressure Vessels)

with a 20–40% reduction in material usage, all while maintaining the strength required to withstand high internal pressures.

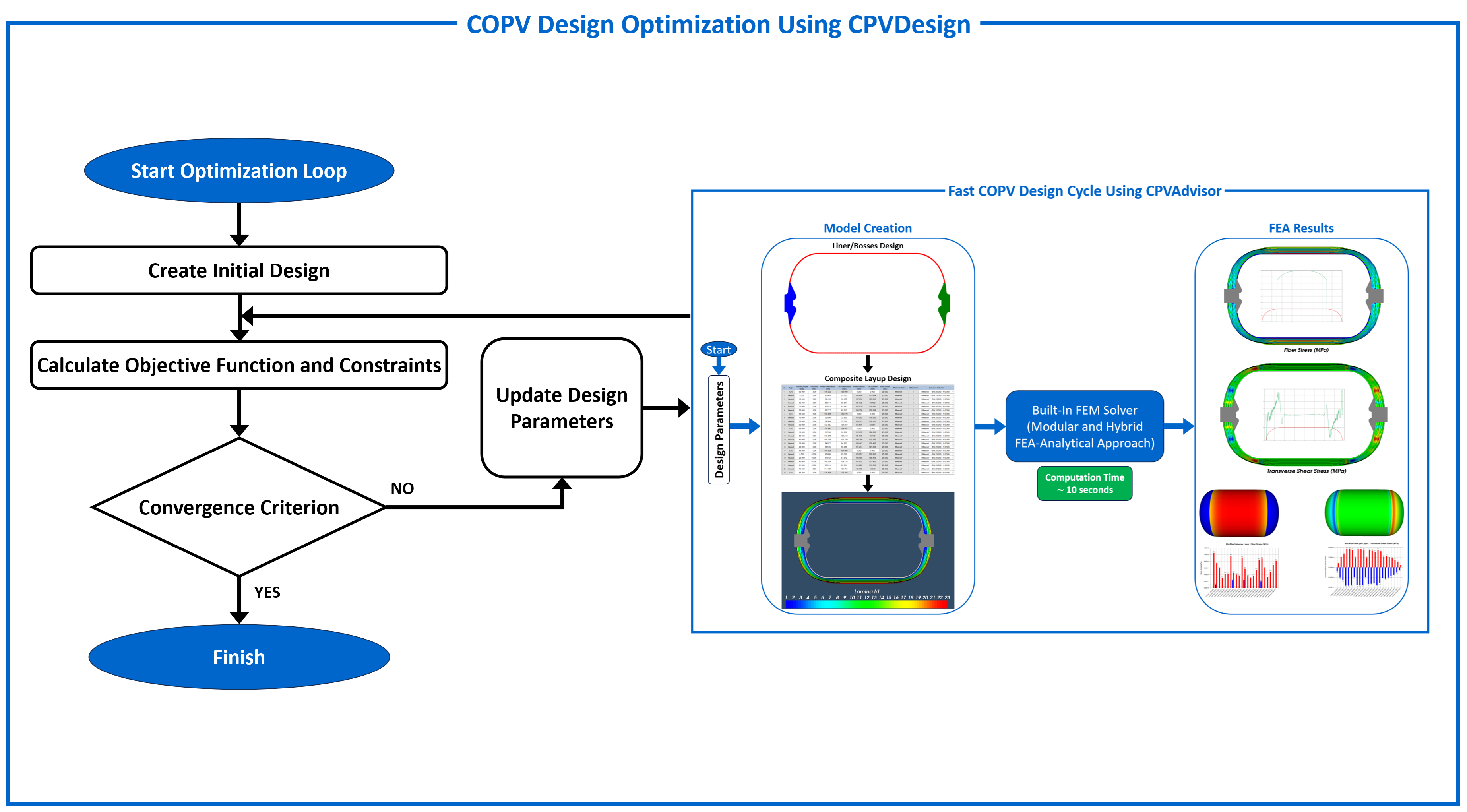

The optimization procedure is powered by a combination of Finite Element Analysis (FEA), using CPVAdvisor’s built-in Model Builder and FEM Solver,

and a custom, multi-objective optimization algorithm. This advanced workflow enables precise evaluation and refinement of designs while

considering critical engineering factors.

✅ Design Parameters:

- Composite Lay-up Configuration

- Winding Angles

- Layer Thicknesses

- Head/Tail Pole Radii

- Axial Edge Positions

- Liner and Dome Geometry

- Material Properties

✅ Optimization Objectives:

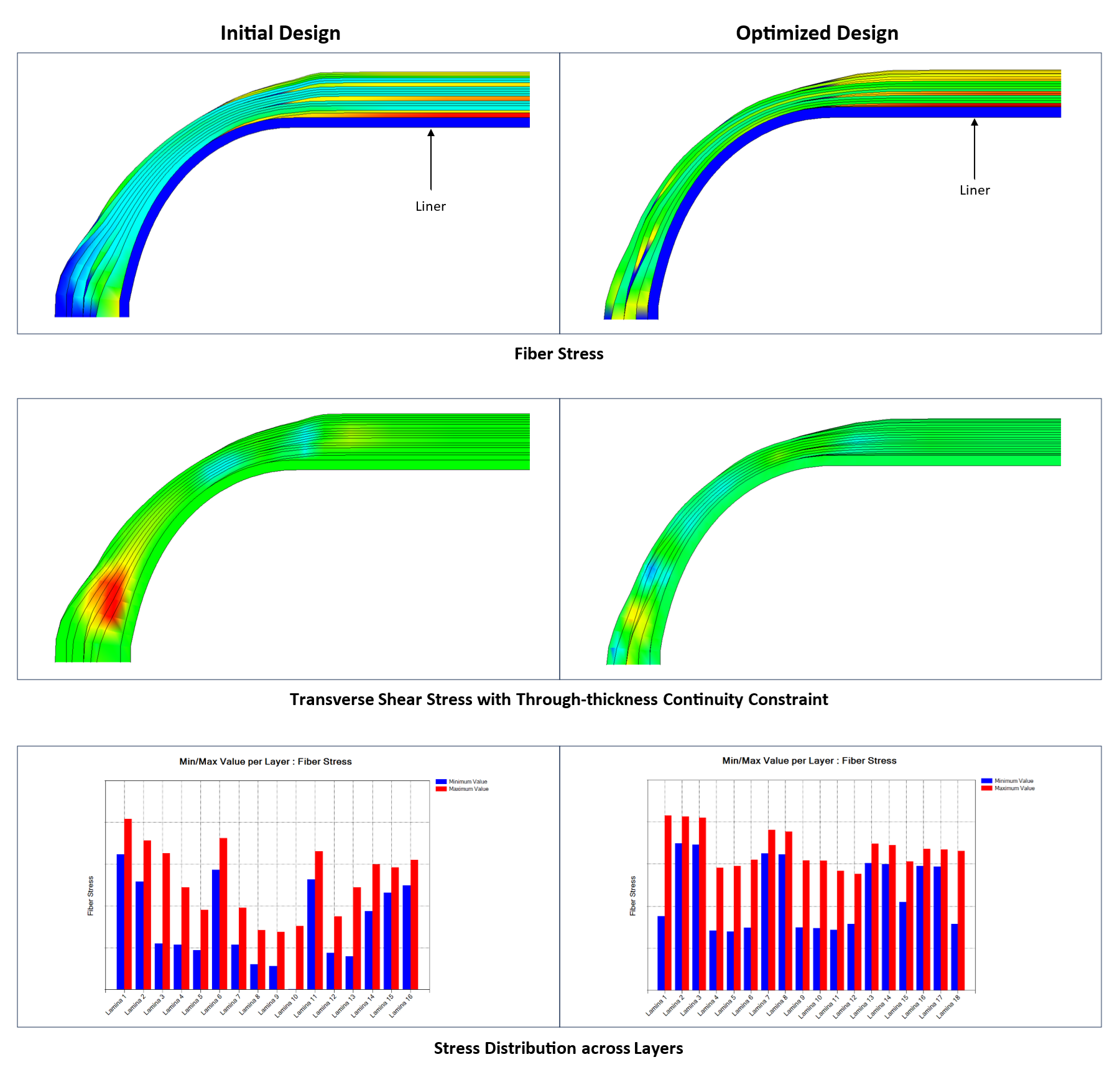

- Minimize fiber stress variance across composite layers

- Ensure uniform stress distribution in each layer

- Reduce overall COPV weight

✅ Design Constraints:

- Must meet failure criteria

- Stay within defined bounds for each parameter

- Stay within specified storage capacity

- Comply with dimensional and size specifications

✅ Initial Design Options:

- User-defined liner and laminate table

- Automatically generated baseline design by CPVAdvisor

Parallel Optimization Capability

Accelerate results through parallel processing, allowing faster convergence and exploration of multiple design paths simultaneously.